Stock Transport Process using SAP EWM-TM Integration

- Aman Jain

- May 29, 2024

- 6 min read

Updated: Jun 7, 2024

Stock Transport Order

Stock Transport Process

A stock transport order (STO) is a form of purchase order where a material is ordered from another plant instead of an external vendor. There is a requirement in the ordering plant and there is a replenishment in the supplying plant. These will need to be matched to each other.

Typically, this type of stock transfer between two plants involves stock management (Using SAP EWM in case of EWM managed Warehouse) and purchasing in the receiving plant. Once the stock in the issuing plant is pick, packed and staged, the goods issue posting in the warehouse management is carried out, typically using shipments or freight order.

A stock transfer includes the following two processes:

· A goods issue to the stock transport order in the issuing plant

· A goods receipt against the stock transport order in the receiving plant

The quantity of stock issued from the issuing plant is first managed as stock-in-transit in the receiving plant. The stock is available as unrestricted stock in the receiving plant only after a goods receipt has been posted in the receiving plant.

Messages Communication between EWM, S/4HANA, TM for Stock Transport Process

In case of embedded EWM (Extended Warehouse Management) and TM (Transportation Management) in S/4HANA, in the latest versions, SAP has tightly integrated the process of Stock Transport between EWM enabled warehouses run using EWM, and transport being done between the warehouses using SAP Transportation Management. The communication based on various business process operations take place between EWM and TM using SOAP proxies triggered using WSRM (Web Services Reliable Messaging) as part of peer-to-peer interaction between EWM, S/4HANA and TM. The step-by-step integration and message exchanges between EWM, S/4HANA and TM for the completion of Stock Transport process between two different warehouses (WH1 and WH2) of the company ABC is shown below.

The various steps involved in the end to end run of the Stock Transport order as shown in Fig 1.2 above, is explained in this blog post below in sequential steps:

1. Create Stock Transport Order in S/4HANA: As the starting step, a stock transport order is created in S/4HANA for shipping the product stock from Warehouse1 (Plant 1) to Warehouse2 (Plant 2) as shown below:

2. Create Replenishment Delivery in S/4HANA: A replenishment delivery is created against the Stock Transport Order using the SAP T-Code: VL10B. This has been shown in the snapshot below:

The execution of this tnx will create the delivery to send the stock from source to destination warehouse (WH1(Plant1)->WH2(Plant2))

Replenishment Delivery can be displayed by clicking the delivery number in the screen above and it will be displayed a shown in the snap below:

3. Replenishment Delivery Replication in embedded EWM: The delivery will be replicated to embedded EWM system and can be displayed using the tnx: /n/SCWM/PRDO using appropriate filters as shown below:

4. Create Freight Unit in embedded TM: The freight units for the replenishment delivery is created automatically in embedded TM based on the integration setting as shown below:

Freight Unit in detail:

5. Plan Freight Unit on Freight Order in embedded TM: Freight Unit is planned in embedded TM on a Freight Order and a carrier and vehicle is assigned to the Freight Order as shown below:

Items updated in the Freight Order

6. Once planning is completed, the Freight Order is set to “Load Planning is Finalized” which triggers the SOAP – “TransportationOrderLoadingAppointmentRequest_In” in embedded EWM.

Set Load Plan to Finalized

“TransportationOrderLoadingAppointmentRequest_Out” sent from Freight Order

Execution status set as “Ready for Loading” in Freight Order

7. Create Transportation Unit for WH1 in embedded EWM: Transportation Unit is created in embedded EWM and replenishment delivery for further processing as shown below:

8. Activate Transportation Unit for WH1 in embedded EWM: Transportation Unit is activated in embedded EWM which triggers the interface communication between EWM and TM for status update in the Freight Order.

Transportation Unit is activated

“TransportationOrderLoadingAppointmentNotification_In” is triggered from embedded EWM to TM to update the Freight Order in embedded TM

9. Report “Arrival” in Freight Order for WH1 in embedded TM: The event – “Arrival” is reported against the Freight Order as shown in snap below:

10. Complete warehouse activities for replenishment delivery in embedded EWM: Various warehouse activities, such as picking, packing, staging, loading and goods issue is completed for the replenishment delivery in embedded EWM as shown in snap below.

Replenishment Delivery before completion of Warehouse Activities

Replenishment Delivery after completion of Warehouse Activities

11. Update replenishment delivery in S/4HANA: Once the goods issue is posted against the replenishment delivery in embedded EWM, the GI status also propagates to LE replenishment delivery and its status is updated.

12. Update freight unit and freight order items in embedded TM: The handling unit information is relayed back from the embedded EWM to embedded TM system and the packaging information is updated in the Freight Unit item level and it also reflects in the Freight Order.

13. Create Inbound Delivery in S/4HANA: As a follow-on automated step from step 11 above, once the GI is posted against the replenishment delivery, “SPED” is triggered and an inbound delivery is created for stock receipt in the destination WH2 (Plant2)

SPED o/p triggered in the replenishment delivery

Inbound Delivery is created for stock receipt in destination plant

14. Inbound Delivery Replication in embedded EWM: Once the inbound delivery is created in LE, it is replicated in embedded EWM so that further processing can be completed for the stock transport process.

15. Depart Transportation Unit from embedded EWM: The Transportation Unit is departed from the checkpoint from embedded EWM using the tnx: /n/SCWM/TU as shown in the snap below.

Transportation Unit in WH1 is Departed from the check-point

“TransportationOrderLoadingAppointmentNotification_In” is triggered from embedded EWM to TM to update the Freight Order in embedded TM

16. Report “Load, Departure” in Freight Order in embedded TM: Once the “TransportationOrderLoadingAppointmentNotification_In” is assimilated by embedded TM, it updates the Freight Order with various events as shown below:

17. Inbound Delivery gets attached to the Freight Units in FO in embedded TM: Once the Inbound Delivery is created in step 12 and all appropriate steps for the Freight Order updated is completed in step 16, the freight units of the initial freight order is attached to the inbound delivery and can be displayed in the document flow in the freight order for the stock transport order.

18. Create Transportation Unit for WH2 in embedded EWM: The embedded TM upon reporting of the “Departed” events from the WH1 location triggers the event – “TransportationOrderLoadingAppointmentRequest_In” for creation of Transportation Unit for WH2 in embedded EWM as shown below.

“TransportationOrderLoadingAppointmentRequest_In” triggered in the Freight Order

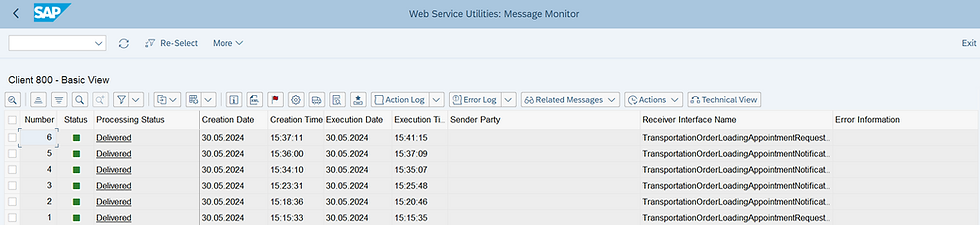

“TransportationOrderLoadingAppointmentRequest_In” monitored in tnx: SRT_MONI

Transportation Unit for WH2 created in embedded EWM

19. Activate Transportation Unit for WH2 in embedded EWM: The Transportation Unit for WH2 is activated in embedded EWM using the tnx: /n/SCWM/TU as shown in snapshot below.

Transportation Unit for WH2 is activated in embedded EWM

“TransportationOrderLoadingAppointmentNotification_In” is triggered from embedded EWM to TM

20. Report “Arrival” in Freight Order for WH2 in embedded TM: Once the “TransportationOrderLoadingAppointmentNotification_In” is assimilated by embedded TM system, the “Arrival” event is updated in the Freight Order as shown in snapshot below.

21. Complete warehouse activities for inbound delivery in embedded EWM: Various warehouse activities, such as unloading, putaway and goods receipt is completed for the inbound delivery in embedded EWM as shown in snap below.

22. Update inbound delivery in S/4HANA: After the inbound delivery goods receipt is posted in embedded EWM, the goods movement information is posted back to LE inbound delivery in S/4HANA as shown below:

23. Update freight unit and freight order items in embedded TM: The Freight Unit and Freight Order status is updated after the associated delivery is updated in S/4HANA.

24. Depart Transportation Unit from embedded EWM: The Transportation Unit is departed from the checkpoint from embedded EWM using the tnx: /n/SCWM/TU as shown in the snap below.

25. Report “Unload, Departure” in Freight Order in embedded TM: Once the “TransportationOrderLoadingAppointmentNotification_In” is assimilated by embedded TM, it updates the Freight Order with various events as shown below

“TransportationOrderLoadingAppointmentNotification_In” is triggered from embedded EWM to TM

"Departure" Event reported in embedded TM

Pre-Requisites for setting up scenario:

EWM Integration Profiles

PPF Profiles for EWM to TM communications

Setup SOAP Services Integration Profile

About Us

We are a group with high end expertise in SAP SCM and our founder "Aman Jain" has years of multiple years in SAP EWM, TM,BN4L and Yard Logistics in both Standalone or S/4HANA in multiple industries across geographies. Being an author of 3 books of EWM on S/4HANA, we have painfully crafted our service so you can be assured of any future issues.

Mail or Call us for this or any other functionality issues you want to discuss, we are always a mail away!

You can also avail trainings and choose your book of EWM on S/4HANA for end user training and your IT team to jumpstart their learning.

Visit the house of Innosight Ltd

Comments